H&B

CORE BUSINESS IS

PRODUCING

SOAPS, BAR SOAP,

SOAP NOODLE

AND GLYCERIN.

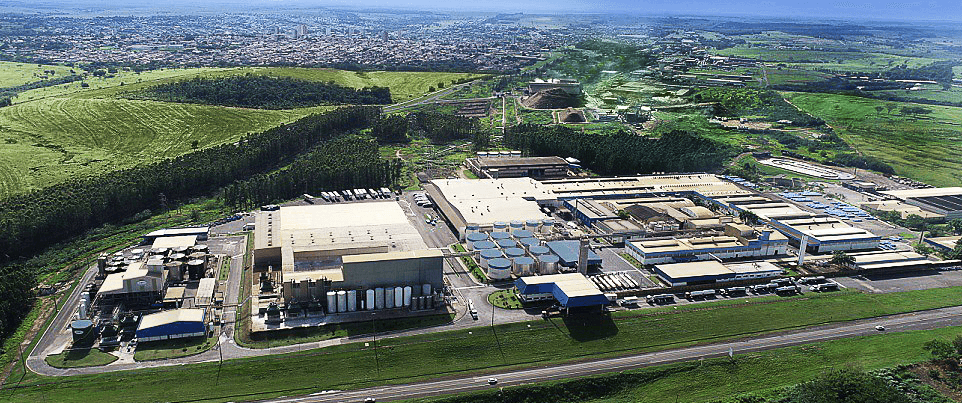

We have modern facilities and 11 robotic production

lines that ensure the production capability

exceeding 190,000 tons per year.

We also meet all customer needs in varied packaging

formats such as flow pacĸ, folding boxes, wrapping paper, and kits.